Hundreds of trains around the world have roofs and cooling systems made in Estonia.

By Holger Roonemaa

Estonia may not be producing trains any longer, as it did a century ago at the Dvigatel factory, but you can find a small company that specialises in building train roofs and cooling systems. Train HVACs are extremely high-tech solutions that need to be designed and tested extra carefully, as the smallest of flaws may mean trouble for passengers and financial loss for carriers. Interconnect Product Assembly’s (IPA) CEO Roman Klepikov tells us more.

Would you please introduce IPA to us?

IPA was established in 1999. We are an independent, privately owned company specialising in the production of electro-mechanical solutions, from simple cable harnesses to complex, fully functional assemblies. The range of services IPA provides includes design, prototyping, serial production, supply chain management and hub sourcing solutions. Starting as a very small company, IPA has managed to grow into a strong firm employing around 200 people and achieving a turnover of €20 million in 2013. 95% of manufactured goods are exported, mainly to the EU, but a number of goods are also delivered to the US, Australian and Canadian markets.

I understand that among other things you also produce train roofs with cooling systems. What does that exactly mean?

One of the products that IPA manufactures is an HVAC (heating air conditioning and ventilation) unit for train manufacturers. Our main customers for these kinds of products are Bombardier, Siemens, Knorr-Bremse, Sigma and Hitachi.

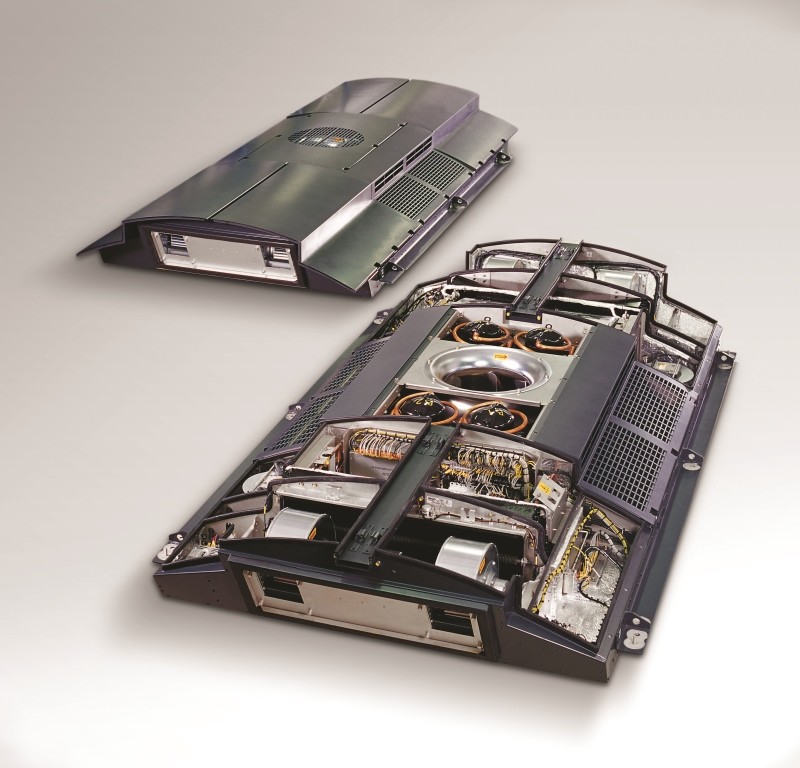

Typically the design of the product is completed by the customer but, when needed, IPA has the skills to design the HVAC unit for the customer. The metal frames are manufactured by IPA’s local partners under the strict supervision of our engineers. The HVAC unit is assembled and completely tested at an IPA facility and delivered straight to the train manufacturing depot. So the only thing the customer has to do is to lift the unit into the roof hole, screw it into place and connect it. The unit is tested and set up for best performance. This is a very complicated product and it might take 150 man-hours to manufacture just one HVAC unit and 30 man-hours to conduct all the tests to guarantee the best possible performance.

Can you tell me as a simple passenger what is the use of your product when I’m travelling on a train?

The product consists of a metal frame made of aluminium or stainless steel, depending on what conditions the train will operate in. It includes the cooling system, heating system, ventilation system and also an emergency mode system. The HVAC unit is 100% automated and the train driver only has to start the train and the rest is done by the unit in order to guarantee a comfortable environment for the passengers. In addition to saloon HVAC units, IPA manufactures train driver HVAC units and all other systems related to the train environment: floor heaters, temperature controllers, extraction units etc.

I find it quite surprising that an Estonian company is producing such systems. How easy or difficult is it to find workers with the necessary skills?

The manufacturing process is fairly complicated indeed, as many aspects and restrictions must be taken into consideration. In general, railway applications have the highest technical and quality requirements. The product must be 100% secure and 100% free of defects. There can be no risk to the passengers. If there is even a small problem, the whole train has to be moved to the depot for maintenance and repair. The cost of a train standing in a depot and not being in service is huge.

The manufacturing process is fairly complicated indeed, as many aspects and restrictions must be taken into consideration. In general, railway applications have the highest technical and quality requirements. The product must be 100% secure and 100% free of defects. There can be no risk to the passengers. If there is even a small problem, the whole train has to be moved to the depot for maintenance and repair. The cost of a train standing in a depot and not being in service is huge.

In order to guarantee high quality and meet all customer expectations, IPA has a team of people who are true professionals in their area. There is a conduit that detects possible design faults in the early design stage, so most of the problems are eliminated before the serial production process. FAI (first article inspection) samples are approved internally with the customer and the train manufacturer. When needed, IPA specialists go to the train builder’s depot in order to ensure the unit fits “properly” to the train and fulfils all the requirements.

The most challenging aspect is the manufacturing process. IPA engineers have worked out a process that always guarantees good and uniform quality, regardless of what type of HVAC is involved. The process requires trained and skilled operators and knowledgeable supervisors. Even more challenging is the testing and set-up process, as this requires good engineering skills, experience and extreme patience, as, sometimes, final adjustments can take much longer than expected.

What is the difference between train HVACs and common cooling systems?

As trains are always moving, micro vibration is always present in products, so if the product is not assembled according to specifications then it can fail easily in one to five years’ time. And if a whole batch is assembled in the same way, this can cause an “epidemic” problem involving the whole train fleet. Nobody wants that. I’m sure you have heard about the HVAC failing in Germany a couple of years ago, when the summer temperature was well above average. There are very strict requirements for project management and also for operations and they are described in the International Railway Industry Standard (IRIS) standards. IPA was audited and awarded by IRIS at the beginning of 2014.

IPA has been growing quite fast. How do you see the company’s future?

IPA has grown very rapidly indeed and we believe the growth will continue for at least the next two years. This requires a lot of effort, as the company must be very flexible to deal with the changes that growth brings.

The company has manufactured HVAC units for over 800 train carriages and IPA’s clients include Knorr-Bremse, Siemens, Hitachi and Bombardier.

I

Brought to you by